ASML Holding reported a fire at its factory that could exacerbate the global shortage of microchips . In fact, the factory is the only supplier of a technology essential to the manufacture of the latter.

The world is experiencing a shortage of computer chips due to the global pandemic and trade difficulties. It also coincided with a period of unprecedented demand, with chip sales hitting $40 billion in January alone. If ASML fails to recover from the fire and supply all the planned machinery, the shortage of products is likely to be prolonged.

ASML Holding denounces a fire in a manufacturing plant

A fire broke out in a factory in Berlin belonging to ASML Holding on the night of January 2, 2022. This phenomenon may intensify an already serious global shortage. Indeed, semiconductors are used in everything from phones to cars.

This supplier said in a press release that it was too early to say what the extent of the damage was and whether it will impact production. “The fire was brought under control overnight and no one was injured during the incident. "It takes a few days to conduct a thorough investigation and make a full assessment."

Vladimir Galabov, of technology analyst Omdia, said the impact of the fire will depend on what was damaged. Whether it affects the most advanced chip manufacturing technology or older equipment is to be considered.

“If it's components used for lithography machines used to make high-end processors, the situation may be slightly better. If the fire-damaged components were used to make the old nodes, the situation is serious. In fact, there is an urgent need to accelerate the manufacturing of these processors.”

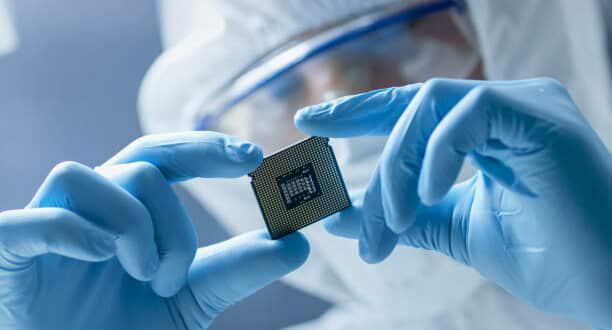

Supplier of vital technology for manufacturing computer chips

Although ASML Holding is not among the big names, the Dutch company is the world's leading supplier of photolithography systems. It is also the only source for more advanced extreme ultraviolet (EUV) lithography machines. These devices are used to etch circuits on silicon wafers. They also help create computer chips used by Apple, IBM and Samsung. In the third quarter of last year, ASML Holding sold 5.2 billion euros worth of this equipment.

Semiconductor factories have limited capacity. The construction of new factories requires massive investments and often takes several years. If ASML cannot supply as many machines as expected, the shortage could last much longer.